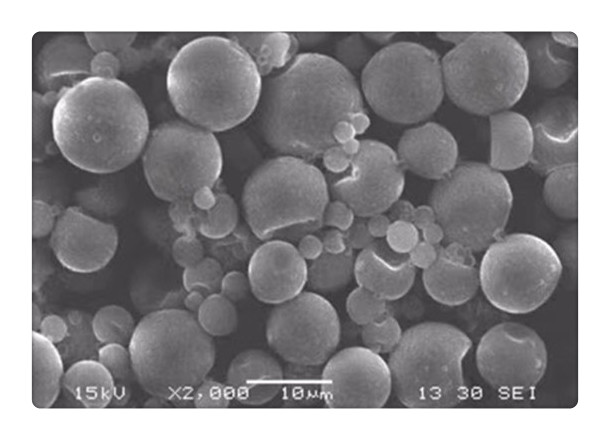

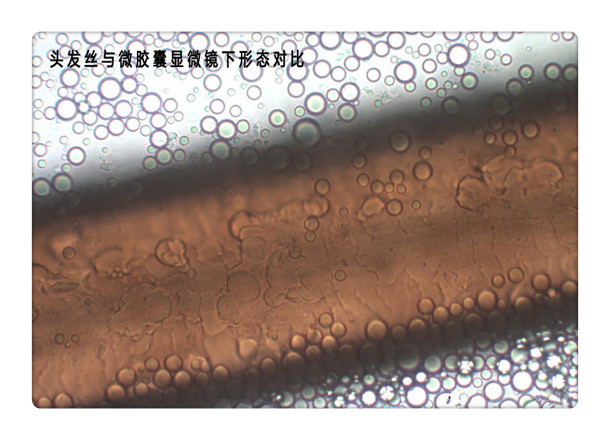

The micro-encapsulation technology is a method generating a layer of continuous thin film of high-molecular compound coated on solid particles, micro liquid droplets or gas, which forms small particles with core-shell structures. The diameter of the micrometer/nano-scale spherical particles with internal core materials is only about one-tenth to one-thousandth of that of hair, which are known as microcapsules (1μm=0.001mm; i.e., 1 μmequals to one thousandth of 1 mm. 1nm=0.001μm; i.e., 1 nm equals to one-thousandth of 1μm). The microcapsules can change the form, density, volume, state and surface properties of internal core materials, and can protect internal core materials from environmental influences. In addition, they can reduce the volatility and contact toxicity by isolating the active ingredients, so as to control the sustainable release. Therefore, the microcapsules can be applied to many fields such as fragrance and flavor, cleaning products, beauty and sunscreen products, food industry, phase-change materials (also known as thermal control materials), pesticides and medicine as well as painting ink and coating products.

The production system and the green and environmentally protective products: In the water-based reaction system, the ecological and green monomers aggregate on surface of oily materials dispersed into nanometer small droplets to form macromolecule wall materials, so as to cover the oily encapsulated materials into microcapsules, with high polymerization reaction degree of no residue of formaldehyde or other toxic components as well as favorable biocompatibility on wall materials.